Accessed from the Warehouse Menu

Warehouse control is the process point for picking, packing and despatching customer orders. Warehouse control is a real-time operation with the list of orders pending despatch updating every 30 seconds.

There are various parameter settings relating to the warehouse functions which can fundamentally change the process flow. These include

Identifying warehouse users

Identifying warehouse supervisors

Picking list sequence

User PIN number process identification

Checking and QA checking process

Load splitting

For full information on the requirements of each parameter see Parameter Settings and view Warehouse Control.

Each despatch note is held within a warehouse LOAD. Dependant on parameters a Load can be made up of various orders as long as they are for the same customer, delivery address, delivery date and priority. This enables the warehouse staff to pick and pack the goods as one but keeping separate despatch notes and invoices. In this instance one carriage charge may be invoices to cover all goods.

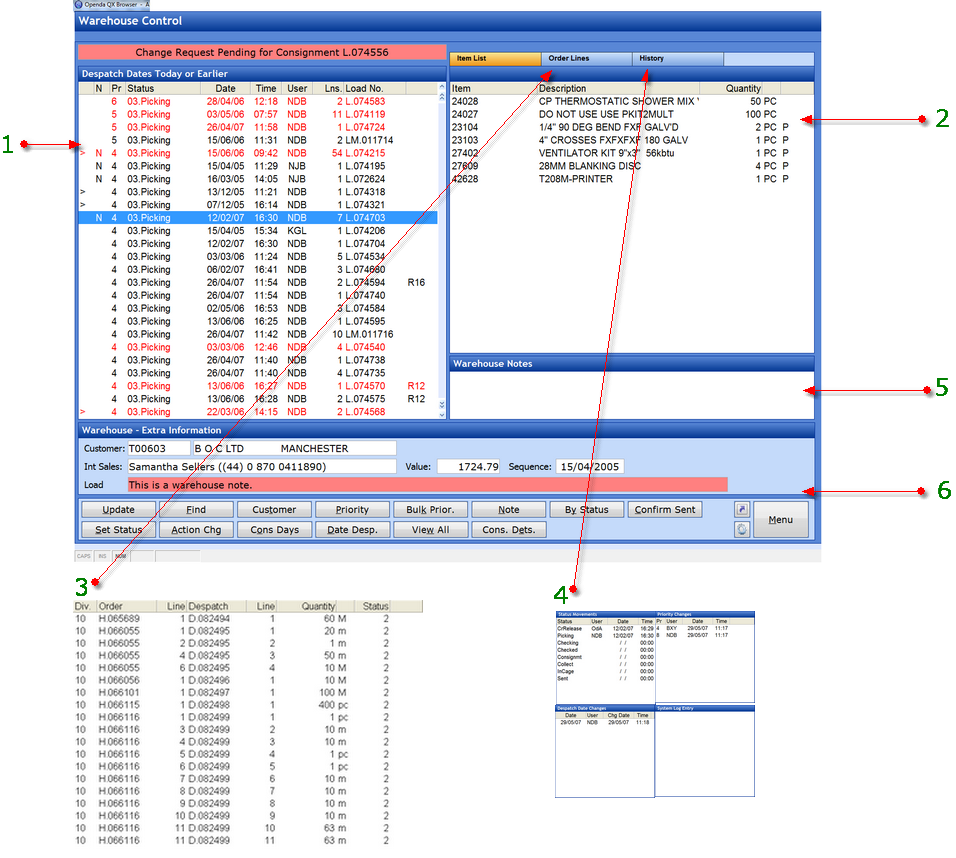

The warehouse control screen is as follows.

1 - Lists all Loads currently awaiting despatch. The list is in Status and then Priority sequence.

1 - Lists all Loads currently awaiting despatch. The list is in Status and then Priority sequence.

> - Identifies entries where other loads exist for the same customer

N - Identifies a Note is set for the load.

PR - The Priority of the despatch. Set by a parameter, the highest priority for each status will be at the top.

STATUS - The current warehouse status of the load.

DATE - The date the status was reached.

TIME - The time the status was reached.

USER - The user responsible for attaining the status. only for statuses above 02-Credit Release, and if PIN number access is in effect.

LNS - The number of item lines on the load.

LOAD NO - The unique load number.

Where a line is coloured RED, it indicates that this load is on a consolidated day. Consolidation days may be set against the customer when a specific week day of despatch is requested. These load are available for view in advance via the CONS DAYS button but will appear within the main screen on the despatch day required. They are accompanied by a RED note field within the extra information (6) frame, confirming the required day and date of despatch.

2 - Item List - all items on the load with its description and quantity. If the quantity is followed by a "P" this indicates the item has not yet been produced to a pick list.

3 - Order Lines - Shows the order and despatch note each of the items on the load relates to.

4 - History - Indicates any changes that have happened to the load.

5 - Any warehouse notes entered against the order lines will be shown here as well as printed on the picking documentation.

6 - Extra information relating to the customer and load.

UPDATE - Move the load from one status to the next. Pin access may be required.

FIND - Search for a particular load number. either enter the number or where available scan the barcode on the picking list.

CUSTOMER - The customer for the highlighted load will be the default, else enter the customer account number and all outstanding loads for the customer will be displayed.

PRIORITY - Change the priority of the load.

BULK PRIOR - Change the priority of multiple loads at the same time.

NOTE - Add a note to the load which will be displayed in RED at the base of the extra information frame.

BY STATUS - Give a selection box of all the statuses. if one selected only loads at that status will be shown.

CONFIRM SENT - For all IN CAGE loads, this option can select an individual load or all loads at IN CAGE status to SENT once sent the loads will be available on the invoice list for invoicing.

SET STATUS - This option, if a warehouse supervision, will allow the status of the load to be moved backwards if re-picking or packing is required.

ACTION CHG - Linked to Change Requests. If a change is made to the sales order while i despatch the warehouse must view and action that change before the load will be allowed to move further in status. This option authorises that change.

CONS DAYS - View loads released onto future consolidated days.

DATE DESP - Amend the date of despatch.

VIEW ALL - View all loads regardless of consolidated date.

CONS DETS - For use on Loads on or after Consignment stage, this option allows the amendment of consignment details such as packages, weights and courier consignment numbers.

Processing a Warehouse Load

By Processing a Load number, it is moved through the various statuses dependant on the parameters set.

All loads enter this process at 02 - Credit Release and UPDATE is the function required to move through the initial stages. If set (parameter), each action of UPDATE will require a 4 digit PIN number to be entered. This PIN number is given during the addition of users and can be amended via user maintenance.

The initial UPDATE will produce the picking list. The picking list displays the item quantity and where set the location of the items required. The sequence of the picking list may be in Item or Bin location (parameter). The option to print a STATIC SHEET may be given (parameter) this sheet is used as a holding sheet for large despatches.

Once all items have been collected UPDATE will take you either to the checking process or direct to checked dependant on Parameters.

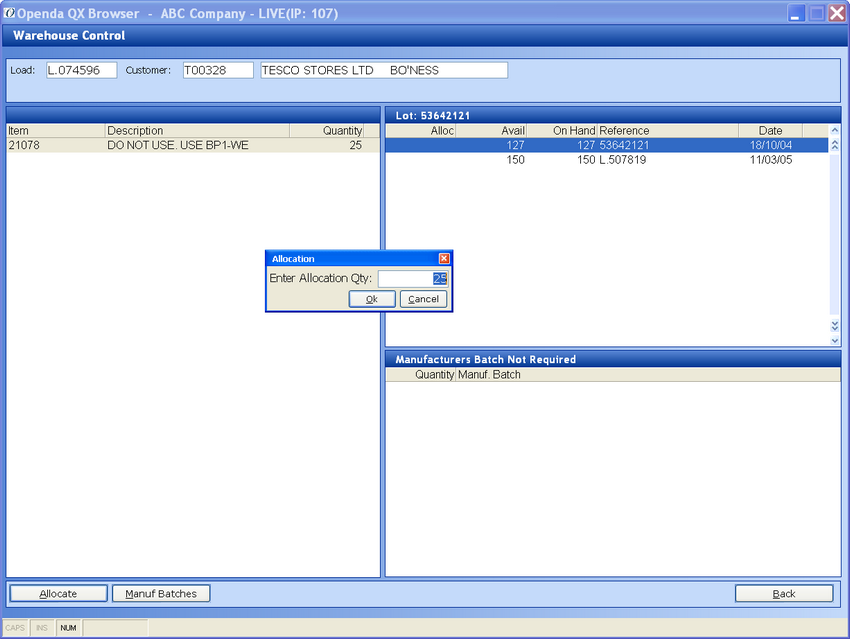

The type of checking process is dependant on whether the items are FiFo or Serial. For Serial or mixed items the checking process is as follows:

Each load item is listed on the left. For serial items the lot picked for despatch must be selected by selecting ALLOCATE LOTS and then highlighting the lot picked, select ALLOCATE and the quantity picked, as shown above.

For FiFO Items lot allocation is not required. A checking process is available to reconfirm the item and quantity.

Once Checked UPDATE will take the status to CONSIGNMENT status where the number of packages, weight, courier and consignment details may be entered. On completion of this the despatch note will be produced. (if subscribed and required, any scanned certification and despatch labels are also produced).

Once the goods have been boxed ready for despatch the load may once again be updated to be placed IN CAGE.

Once the goods have left the building CONFIRM SENT should be selected for one or all and the load can be made available for invoicing.