Accessed via Bill Of Materials from the Manufacturing Menu - Not available for QXLite

When adding a new BOM the manufactured item number must first be selected. To select a manufactured item it must first have been created, this is achieved through the Item Maintenance option. A BOM item must be classed as a Stock Item and it must be added into the warehouse for the Finished Goods. Against every warehouse item is a Re-Order Type. For BOM Items this Re-Order Type will require setting to "P" - Processed Part.

On ADD from the BOM screen a warehouse must first be selected, then a list of all items set as Processed Parts within that warehouse will be displayed. Using the GO TO, locate the item required and SELECT.

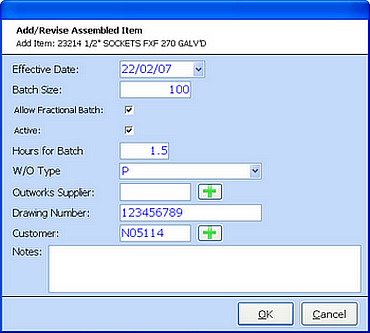

The following screen will then be displayed.

EFFECTIVE DATE - Defaulted to the addition date.

BATCH SIZE - The manufactured batch quantity upon which component calculations will be made.

ALLOW FRACTIONAL BATCH - If set a works order added for this item will not have to be a multiple of the batch size.

ACTIVE - Selecting will set the BOM as Active and visa versa.

HOURS FOR BATCH - Projected manufacture time, this is for cost projection, but is amendable at works order completion.

W/O TYPE - Production for in-house manufacturing, Outwork for manufacturing by external contractor.

OUTWORKS SUPPLIER - The account number of the external contractor - Outwork only.

DRAWING NUMBER - Free field for holding drawing numbers etc.

NOTES - Free text notes field.

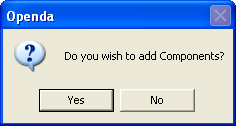

On OK the question is asked

If NO the header is created for future component input. If YES selection of the first component is required.

Adding Components

Accessed either following the creation of a new BOM header or via ADD from the COMPONENT option on Bill Of Materials.

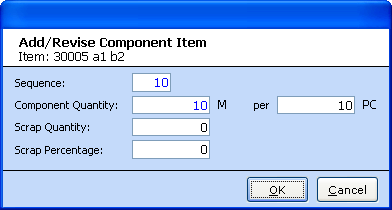

First locate and select the first component for the BOM, the following entry screen will then be displayed:

SEQUENCE - Automatically defaulted to multiples of 10, this decides the order in which the components are seen within the component list. By changing the Sequence to numbers higher or lower than another component will alter the component sequence order.

COMPONENT QUANTITY - Enter the amount of the component needed to complete the batch quantity (PER).

PER - Shows the Batch quantity required for the BOM. Entered during the addition of the BOM header.

SCRAP QUANTITY - The amount of component waste expected during the manufacturing process.

SCRAP PERCENTAGE - The percentage of component waste expected during the manufacturing process.

This completes the Component ADD process, BACK will return you to the main BOM screen. On initial entry the option to add Process Costs will be given.

Adding Process Costs

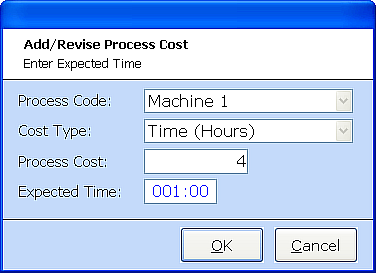

Accessed either during BOM addition and vie the MAINT.COSTS option

There are various types of Process Code such as Labour, Machine and Outworker. Against each of these a Cost Type can be set such as:

BATCH - This relates the cost entered to the Batch Quantity and will calculate the value based on the % quantity made of the Batch Quantity.

TIME - This relates the cost to a period of time and then calculate against the time taken to create the item.

PIECEWORK - A cost per item made.

WORKS ORDER - A set cost against the Works Order.

Once the Process Code and Cost Type are selected the Process Cost can be added. for TIME related Cost Types the expected Hours for completion must be added.