Accessed from the Inventory Menu - Not available for QXLite

This warehouse transfer option allows you to transfer goods out of one warehouse and into another in two stages. This allows for any time lapse required for physical transportation. If a quick "one step" warehouse transfer option is required this is available through the Adjustment option.

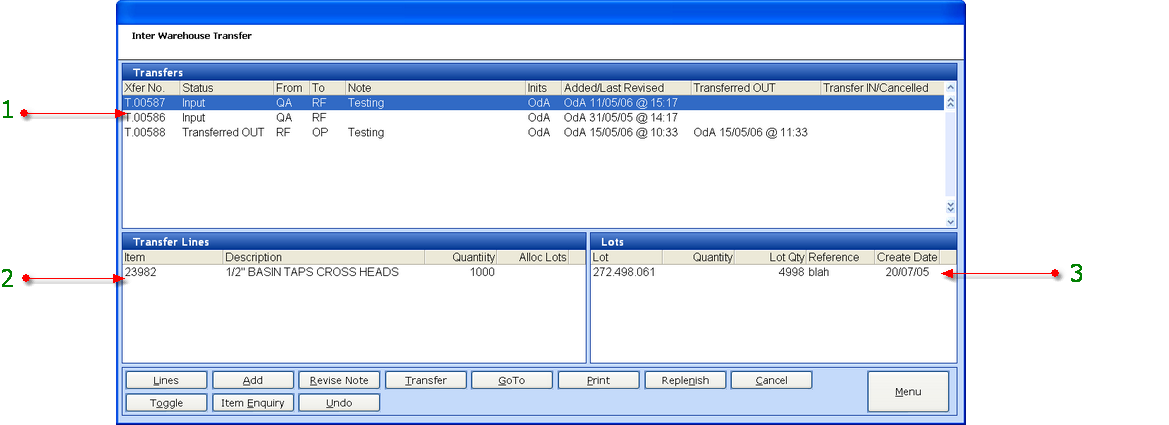

Transfers already in progress are shown with their current status

1 - All transfers - The initial screen shows transfers still in progress, while the TOGGLE option will show all transfers in progress, complete and cancelled. Status options are:

Input - Transfer added but not yet actioned.

Transferred OUT - Goods removed from start warehouse but not yet received into end warehouse.

Transferred IN - Goods received into end warehouse, transfer is now complete.

Cancelled - Transfer added but not carried out.

Each transfer is given a unique identifier and each process is date, time and user stamped.

2 - The items and quantities related to the transfer.

3 - For Serial items, the lot to be moved.

Adding and Processing a Warehouse Transfer

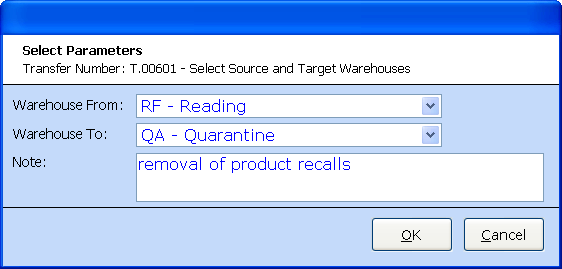

To add a new warehouse transfer select ADD.

Firstly the transfer out and transfer in warehouse need to be selected. Any note required against the transfer may be added at this point.

Each item for transfer must then be selected.

Once all items have been added the PRINT option will produce a PICKING LIST to allow all items to be collected from the warehouse.

For serial lot traceable items the Lots picked must be specified prior to the transfer being performed. LOTS is accessed via the LINES view.

Once all items have been picked and are ready for transfer, the TRANSFER option will be selected. At this point the status will be Transferred OUT. This will be visible not only in the transfer screen but also in the Item UAM.

On delivery of the goods to the end warehouse, the PRINT option will produce a PUT AWAY list to allow the goods to be located in the new warehouse. TRANSFER can be selected throughout this process, completing the warehouse transfer which will be reflected in the end warehouse stock levels.

Further options are as follows:

UNDO - This option will take back the process / status from Transfer OUT to INPUT.

CANCEL - Available only for unallocated transfers at status INPUT

REPLENISH - This option will build a list of items required for bin replenishment. Used when bulk quantities are held in a separate warehouse.